ON THE USE OF NANOTECHNOLOGIES TO PRODUCE STRESS AND STRAIN SENSITIVE CEMENTITIOUS MATERIALS

Questa tesi di dottorato ha vinto il primo premio al concorso Fedderbeton - ACI IC "Innovation in Concrete Structures and Cementitious Materials" del 2014

The objective of this research project is the implementation of new nanotechnologies to modify cement-based sensors.

The idea is to design sensors for the global monitoring of structural health in R/C structures (Structural Health Monitoring), able to overcome the well-known drawbacks of typical monitoring systems like reduced durability, limited number of the sensors, difficulty of access and high cost.

The new sensor is based on smart cement-based materials containing MultiWalled Carbon NanoTubes (MWCNTs). This technology allows to transfer the selfsensing property of biological systems into structural engineering, by allowing the transformation of the surface of concrete structures into an unlimited set of potential embedded sensors.

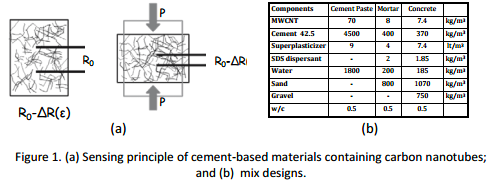

This self-monitoring function is achieved by correlating the variation of the applied stresses with the variation of appropriate parameters and properties of the material, first of all its electrical resistance (Fig. 1a).

Nano-reinforced cementitious materials are both conductive and piezoresistive.

Through the changes in the resistance or in the electrical resistivity, strain and stress states can be measured. In this way, damage evolution and microcracking can be monitored.

Many properties of the cementitious materials, such as the electrical properties, are affected by their micro- and nano-behavior [1]. Adding nanofibers, such as MWCNTs, to cementitious matrices allows to modify the electrical properties [2]. A number of past studies [5] has been about composite materials reinforced with glass and carbon fibers. In 1993 [6], Fu and Chung started a research project about strain sensitivity of cement reinforced with carbon fibers. Due to their very small size, nanoparticles tend to agglomerate and the problem of a suitable fiber dispersion becomes critical [4]. Physical products can help in fiber dispersion.

Above a certain volume fraction (percolation threshold), nanoparticles start creating a net and the composite material becomes electrically conductive. The literature shows that the nano-modified cementitious materials are promising if properly designed and manufactured [7-8].

... READ THE ARTICLE